Project engineering at Volcon Pvt. Ltd. Is designed and developed to execute and facilitate top-quality engineering solutions in a varied range of industries, while trained professionals design and develop specialized project engineering solutions for improvised management and execution of production processes, our proven project management methodology and approach empower and embraces proprietary methods and standards to establish solutions which are tailored made to your specific needs and industry specifications.

Disciplined and dedicated trained engineers design new processes and systems with a rigorous and extensive research-based project management approach enabling us to procure effective and efficient solutions for all.

A carefully and thoroughly crafted outline of detailed plans for each project, with specific milestones for each stage and strong communication, bridges the gap of efficiency and effectiveness in your project management and enables us to complete the project on due time with optimum and maximized results.

IOT Projects

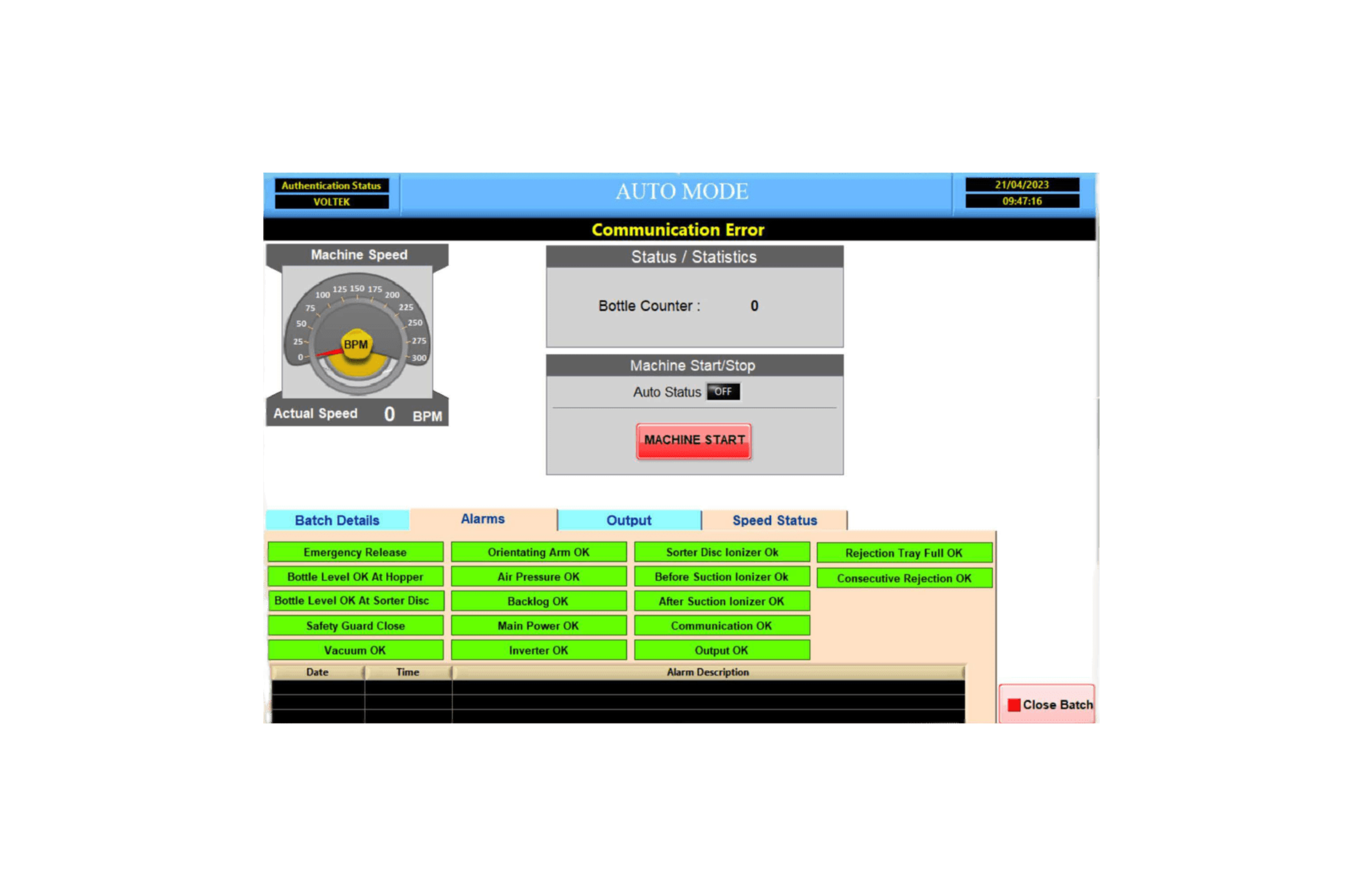

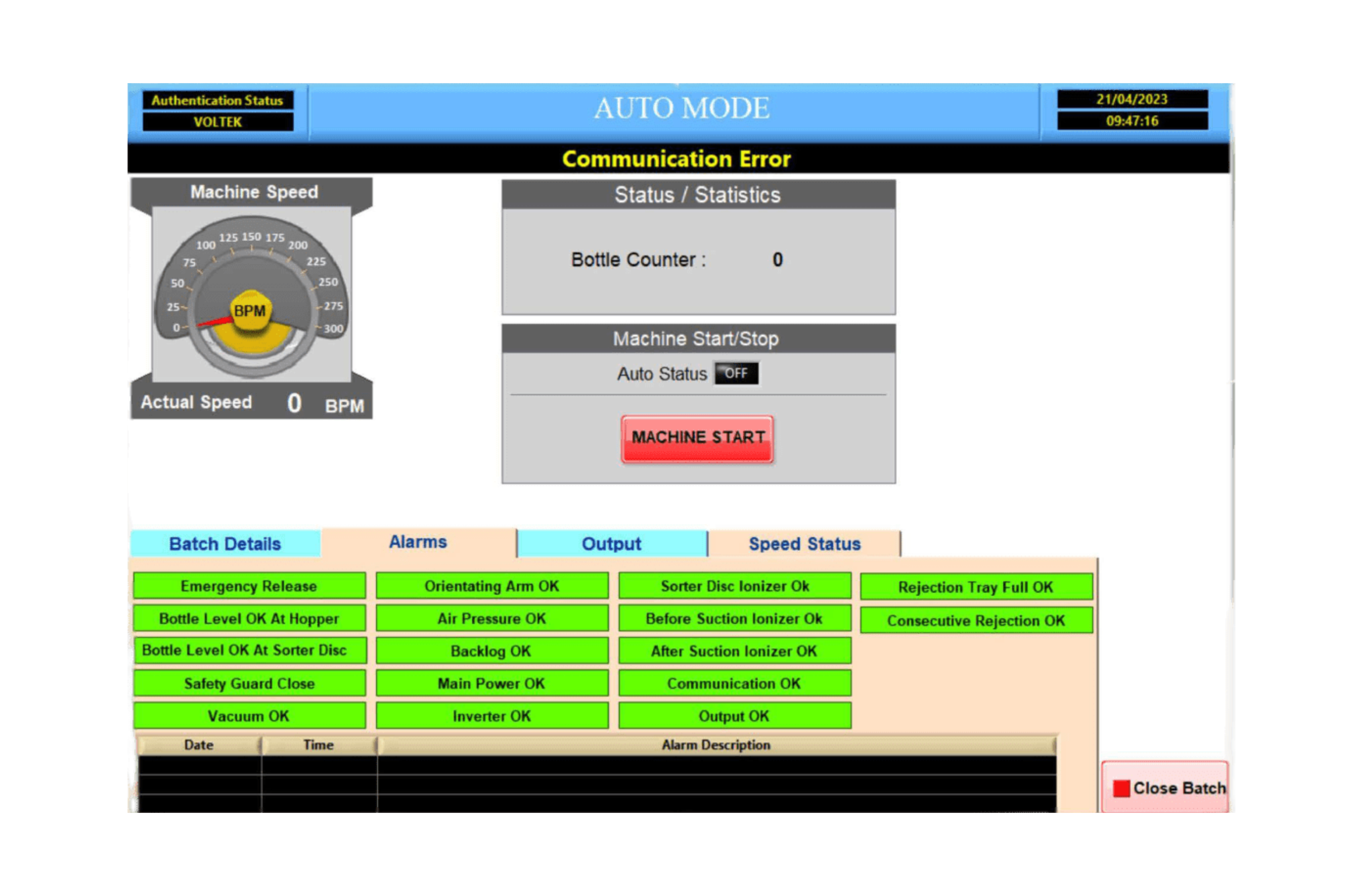

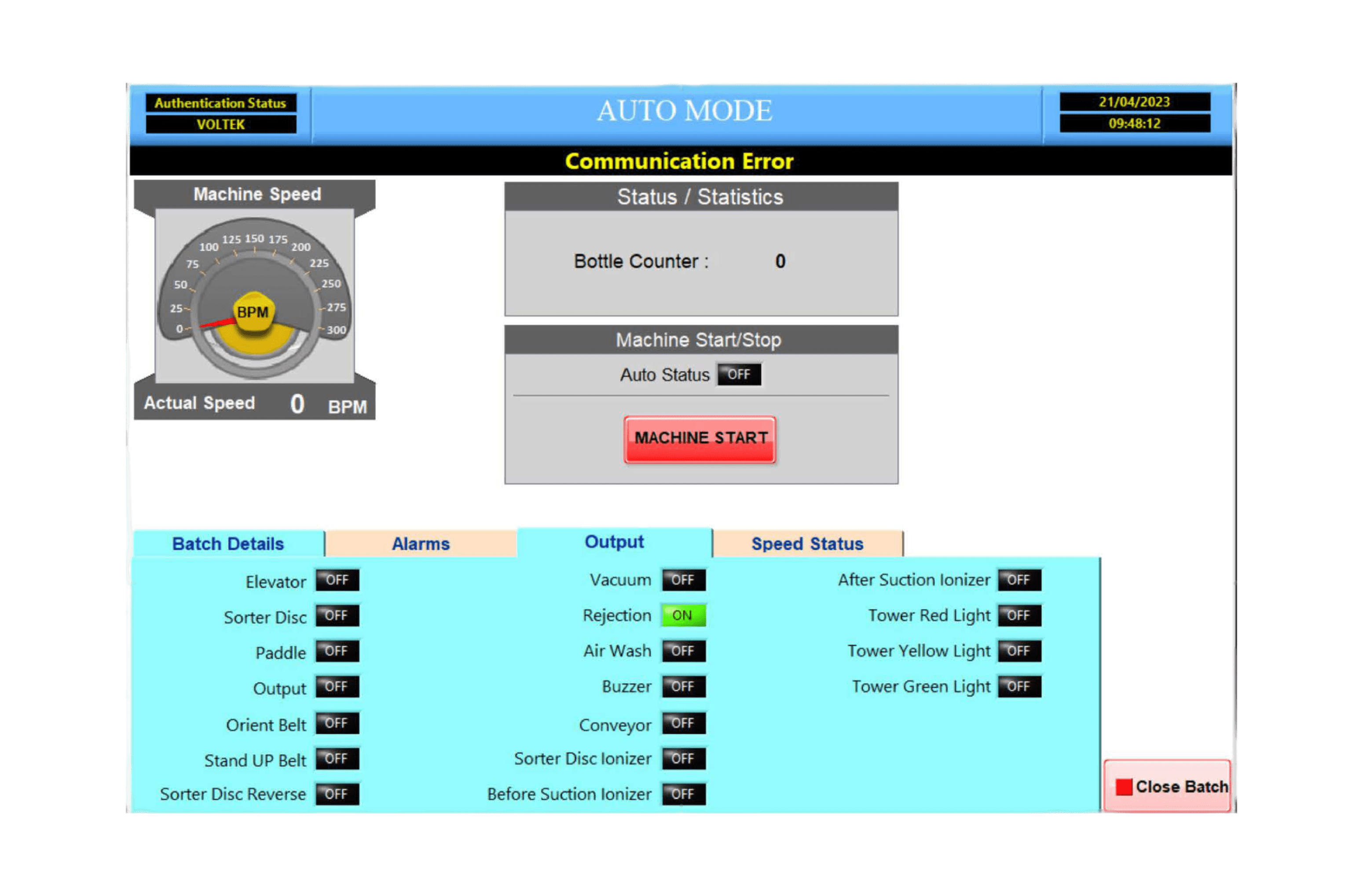

Industrial control systems play a crucial role in modern manufacturing and infrastructure sectors. These systems rely on the integration of Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) to automate processes, monitor equipment, and ensure operational efficiency. In this project, we will explore the world of PLC SCADA projects and highlight their significance in enhancing productivity, improving safety, and optimizing control in various industries. The main objective of PLC SCADA projects is to develop customized automation solutions that streamline industrial processes, enable real-time monitoring, and facilitate informed decision-making. By leveraging PLCs and SCADA systems, we aim to enhance efficiency, reduce downtime, and improve overall system performance. Volcon has been doing Various Automation Projects

- Manufacturing Automation: Developing automation solutions for assembly lines, packaging systems, and material handling processes. PLCs control the machinery, while SCADA systems provide real-time data visualization, alarm management, and performance monitoring.

- Energy Management: Implementing PLC SCADA solutions for power plants, renewable energy systems, and distribution networks. This enables efficient control of power generation, load balancing, fault detection, and remote monitoring of substations.

- Water and Wastewater Management: Utilizing PLCs and SCADA systems to automate water treatment plants, pumping stations, and distribution networks. This ensures efficient operation, precise control of chemical dosing, real-time monitoring of water quality parameters, and timely response to system failures.

- Packaging Automation: Packaging automation is the process of replacing repetitive tasks with automated systems, with the goal of eliminating tedious and demanding duties. In the process, this frees up workers to focus on more strategic tasks.

content2

content3

Industrial control systems play a crucial role in modern manufacturing and infrastructure sectors. These systems rely on the integration of Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) to automate processes, monitor equipment, and ensure operational efficiency. In this project, we will explore the world of PLC SCADA projects and highlight their significance in enhancing productivity, improving safety, and optimizing control in various industries. The main objective of PLC SCADA projects is to develop customized automation solutions that streamline industrial processes, enable real-time monitoring, and facilitate informed decision-making. By leveraging PLCs and SCADA systems, we aim to enhance efficiency, reduce downtime, and improve overall system performance. Volcon has been doing Various Automation Projects

Industrial control systems play a crucial role in modern manufacturing and infrastructure sectors. These systems rely on the integration of Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) to automate processes, monitor equipment, and ensure operational efficiency. In this project, we will explore the world of PLC SCADA projects and highlight their significance in enhancing productivity, improving safety, and optimizing control in various industries. The main objective of PLC SCADA projects is to develop customized automation solutions that streamline industrial processes, enable real-time monitoring, and facilitate informed decision-making. By leveraging PLCs and SCADA systems, we aim to enhance efficiency, reduce downtime, and improve overall system performance. Volcon has been doing Various Automation Projects

- Manufacturing Automation: Developing automation solutions for assembly lines, packaging systems, and material handling processes. PLCs control the machinery, while SCADA systems provide real-time data visualization, alarm management, and performance monitoring.

- Energy Management: Implementing PLC SCADA solutions for power plants, renewable energy systems, and distribution networks. This enables efficient control of power generation, load balancing, fault detection, and remote monitoring of substations.

- Water and Wastewater Management: Utilizing PLCs and SCADA systems to automate water treatment plants, pumping stations, and distribution networks. This ensures efficient operation, precise control of chemical dosing, real-time monitoring of water quality parameters, and timely response to system failures.

- Packaging Automation: Packaging automation is the process of replacing repetitive tasks with automated systems, with the goal of eliminating tedious and demanding duties. In the process, this frees up workers to focus on more strategic tasks.

Projects

- Servo Based Piston Filling Machine [up to 12 Axis]

- Servo Based Rotary capping Machine [up to 12 Axis]

- Servo Gear Based Linear Liquid Filling Machine [up to 8 Axis]

- Flow Meter Based Rotary Liquid Filling Machine

- Flow Meter Based Linear Liquid Filling Machine

- Motion Filler Machine

- Pharma Utility Equipment

- Pharma Process Equipment

In today’s advanced technological landscape, industries are constantly seeking innovative solutions to enhance efficiency, improve quality control, and streamline operations. One such ground breaking technology is the use of vision systems. Leveraging the capabilities of cameras and intelligent image processing algorithms, vision systems have emerged as a game-changer in various industrial sectors. In this article, we will explore the applications and benefits of vision systems in industries, highlighting their transformative impact on automation, inspection, and process optimization. Vision systems play a vital role in automating industrial processes by providing machines with the ability to “see” and interpret visual information. Here are some key areas where vision systems have made significant contributions:

In today’s advanced technological landscape, industries are constantly seeking innovative solutions to enhance efficiency, improve quality control, and streamline operations. One such ground breaking technology is the use of vision systems. Leveraging the capabilities of cameras and intelligent image processing algorithms, vision systems have emerged as a game-changer in various industrial sectors. In this article, we will explore the applications and benefits of vision systems in industries, highlighting their transformative impact on automation, inspection, and process optimization. Vision systems play a vital role in automating industrial processes by providing machines with the ability to “see” and interpret visual information. Here are some key areas where vision systems have made significant contributions:

- Robotics and Assembly: Vision-guided robots are being used to automate complex assembly tasks. Vision systems provide robots with the ability to accurately locate and pick objects, perform precise alignments, and handle intricate manipulations.

- Pick and Place Operations: Vision systems enable automated picking and placing of objects based on their size, shape, colour, or barcode information. This is particularly useful in industries such as logistics, warehousing, and e-commerce.

- Quality Inspection: Vision systems are extensively used in quality control processes to identify defects, inconsistencies, or deviations from desired specifications. They can perform high-speed inspections, detect surface defects, measure dimensions, and validate product labeling.

- Packaging and Labelling: Vision systems ensure accurate packaging by verifying the presence, position, and correctness of labels, barcodes, or printed information. They can also inspect packaging for defects, seal integrity, and proper placement of products.

- Defect Detection: Vision systems can identify defects, such as scratches, dents, or color variations, in products or components. They provide reliable and consistent inspection results, reducing reliance on manual inspections and enhancing product quality.

- Optical Character Recognition (OCR): Vision systems equipped with OCR capabilities can read and interpret text from images, labels, or packaging. This is useful for validating product information, tracking serial numbers, or verifying printed codes.

- Dimensional Measurement: Vision systems accurately measure dimensions, angles, or contours of objects in real-time. This ensures that products meet precise specifications and comply with quality standards.

- Surface Inspection: Vision systems employ advanced algorithms to inspect the surface quality of materials, such as textiles, metal surfaces, or printed circuit boards. They can identify surface defects, uneven textures, or blemishes that may impact product performance.

- Process Monitoring: Vision systems provide real-time monitoring of production lines, detecting anomalies, identifying bottlenecks, and alerting operators of potential issues. This facilitates proactive maintenance, minimizes downtime, and maximizes overall equipment effectiveness (OEE).

- Traceability and Track-and-Trace: Vision systems can capture and record data related to product identification, packaging, and labeling. This information facilitates traceability throughout the supply chain, ensuring compliance with regulations, and enabling efficient recall management, if necessary.

- Sorting and Classification: Vision systems can accurately sort and classify objects based on predefined criteria such as size, shape, color, or visual characteristics. This is beneficial for sorting products, segregating components, or categorizing items based on quality levels.

- Improved Quality and Consistency: Vision systems deliver consistent and reliable inspection results, reducing human error and variability in quality control processes. This leads to improved product quality and customer satisfaction.

- Increased Efficiency and Productivity: Vision systems automate repetitive and labor-intensive tasks, freeing up human resources to focus on more value-added activities. This results in increased productivity, reduced cycle times, and improved throughput.

- Cost Reduction: By automating inspections and reducing reliance on manual labor, vision systems help minimize production errors, rework, and scrap. This leads to cost savings and improved profitability for industries.

- Advanced Analytics and Optimization: Vision systems generate vast amounts of data that can be leveraged for advanced analytics, process optimization, and predictive maintenance. The insights gained from this data can drive continuous improvement initiatives and facilitate data-driven decision-making.

- Future Innovations: The ongoing advancements in artificial intelligence (AI) and machine learning (ML) are unlocking new possibilities for vision systems. These technologies enable the systems to learn and adapt, improving accuracy, expanding capabilities, and opening doors for further automation in industries.

Projects

- Printing Inspection

- Drop Measurements

- Bottle Inspection[machine learning Based]

- Black Beads Counting

- Barcode Inspection

The Internet of Things (IoT) has revolutionized industries by enabling the connection of physical devices and systems to the internet, allowing for real-time data exchange and remote control. IoT projects have emerged as a powerful tool for optimizing operations, improving efficiency, and driving innovation across various industries. In this article, we will explore the applications and benefits of IoT projects in industries, highlighting their transformative impact on asset management, predictive maintenance, and resource optimization.

The Internet of Things (IoT) has revolutionized industries by enabling the connection of physical devices and systems to the internet, allowing for real-time data exchange and remote control. IoT projects have emerged as a powerful tool for optimizing operations, improving efficiency, and driving innovation across various industries. In this article, we will explore the applications and benefits of IoT projects in industries, highlighting their transformative impact on asset management, predictive maintenance, and resource optimization.

*Transforming Asset Management*

IoT projects have significantly transformed asset management practices, enabling industries to monitor, track, and manage their assets in real time. Here are some key areas where IoT projects have made a profound impact:

1. Asset Tracking: IoT-enabled sensors and GPS technology allow industries to track the location and movement of assets, such as vehicles, equipment, or inventory. Real-time asset tracking ensures better utilization, reduces loss or theft, and enables efficient inventory management.

2. Condition Monitoring: IoT sensors can be deployed on assets to continuously monitor parameters such as temperature, humidity, vibration, or energy consumption. This real-time data helps predict maintenance needs, identify potential failures, and optimize asset performance.

3. Supply Chain Visibility: IoT projects facilitate end-to-end visibility and transparency in the supply chain by integrating sensors and data analytics. Industries can monitor the movement of goods, track environmental conditions during transportation, and optimize logistics operations.

*Enabling Predictive Maintenance*

IoT projects play a crucial role in shifting maintenance practices from reactive to proactive by enabling predictive maintenance strategies. Here’s how IoT projects have revolutionized maintenance practices:

1. Remote Monitoring: IoT devices enable remote monitoring of equipment, machinery, or critical infrastructure. Real-time data on performance, operating conditions, or anomalies helps detect potential failures, allowing for timely maintenance interventions.

2. Predictive Analytics: IoT projects leverage data analytics and machine learning algorithms to identify patterns, detect anomalies, and predict equipment failures. This enables industries to schedule maintenance activities based on actual asset conditions, reducing downtime and optimizing maintenance costs.

3. Condition-Based Maintenance: IoT sensors provide continuous data on asset conditions, allowing maintenance actions to be performed based on asset health rather than fixed schedules. Condition-based maintenance improves asset reliability, extends lifespan, and minimizes unnecessary maintenance activities.

*Optimizing Resource Management*

IoT projects enable industries to optimize resource management, leading to improved efficiency and sustainability. Here are some key applications:

1. Energy Management: IoT devices monitor energy consumption patterns, detect wastage, and optimize energy usage in industries. This allows for energy-efficient operations, cost savings, and reduced environmental impact.

2. Water Management: IoT projects assist industries in monitoring water usage, identifying leaks or anomalies, and optimizing water consumption. This enables sustainable water management practices and reduces water-related risks.

3. Environmental Monitoring: IoT sensors facilitate real-time monitoring of environmental factors, such as air quality, noise levels, or pollutant levels. Industries can take proactive measures to ensure compliance with regulations, minimize environmental impact, and enhance the well-being of employees and communities.

Automation Projects

Industrial control systems play a crucial role in modern manufacturing and infrastructure sectors. These systems rely on the integration of Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) to automate processes, monitor equipment, and ensure operational efficiency. In this project, we will explore the world of PLC SCADA projects and highlight their significance in enhancing productivity, improving safety, and optimizing control in various industries. The main objective of PLC SCADA projects is to develop customized automation solutions that streamline industrial processes, enable real-time monitoring, and facilitate informed decision-making. By leveraging PLCs and SCADA systems, we aim to enhance efficiency, reduce downtime, and improve overall system performance. Volcon has been doing Various Automation Projects

- Manufacturing Automation: Developing automation solutions for assembly lines, packaging systems, and material handling processes. PLCs control the machinery, while SCADA systems provide real-time data visualization, alarm management, and performance monitoring.

- Energy Management: Implementing PLC SCADA solutions for power plants, renewable energy systems, and distribution networks. This enables efficient control of power generation, load balancing, fault detection, and remote monitoring of substations.

- Water and Wastewater Management: Utilizing PLCs and SCADA systems to automate water treatment plants, pumping stations, and distribution networks. This ensures efficient operation, precise control of chemical dosing, real-time monitoring of water quality parameters, and timely response to system failures.

- Packaging Automation: Packaging automation is the process of replacing repetitive tasks with automated systems, with the goal of eliminating tedious and demanding duties. In the process, this frees up workers to focus on more strategic tasks