Volcon manufacturing front harbors software and hardware manufacturing solutions required for any industrial automation to run smoothly. Designed and developed programmable and customizable, our manufacturing automation and electrical solutions are the best possible tools to maximize output with cost-effectiveness and efficiency.

Our embedded solution department ensures industrial automation, security and scrutiny process management, telecommunication, and instrumentation are running without delays and helps the business gain momentum of continuous operation.

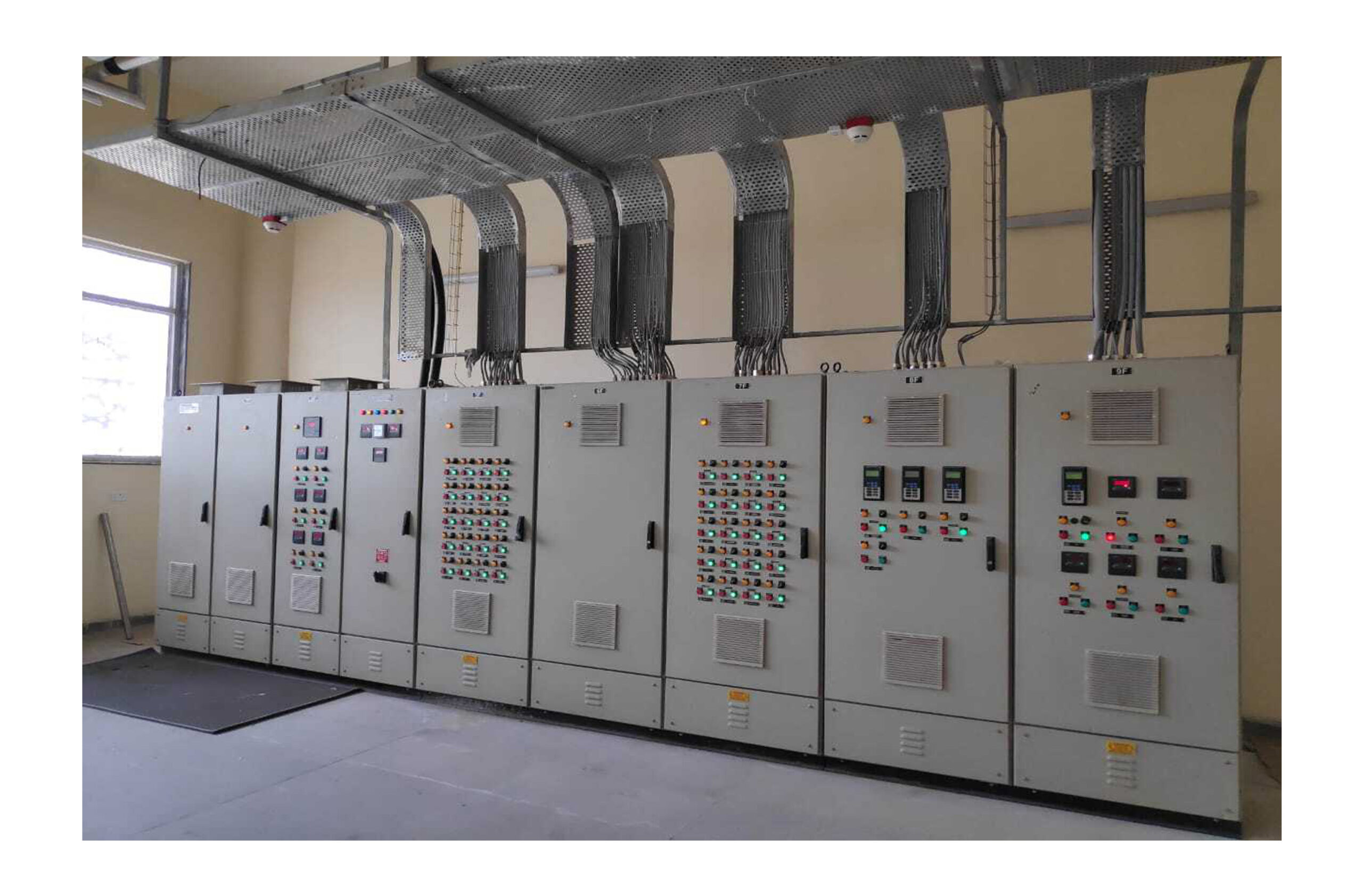

Control panel manufacturing at Volcon procures a higher level of monitoring and control of a varied range of factors affecting production ensuring that you can define, organize and meet your production objectives with optimum satisfaction.

Smart and technologically advanced vision procures a clear and systematic approach towards procuring the best eye for viewing your production process management, while also enabling detailed definition of minute details of your products ensuring quality control and maintenance of large-size manufacturing chains, and meeting demands with efficiency without delays.

Embedded solutions have become instrumental in the realm of automation, providing powerful tools and technologies that enable seamless integration, intelligent control, and enhanced performance. These solutions combine hardware and software components to create intelligent systems capable of automating processes across various industries. In this article, we will explore the significance of embedded solutions in automation, their applications, and the benefits they bring to organizations. Embedded solutions refer to the integration of computing systems and software directly into devices, equipment, or machinery to enable automation and control. These solutions are designed to perform specific functions, offering real-time monitoring, data processing, and decision-making capabilities. Embedded systems can be found in a wide range of applications, from industrial automation and robotics to home appliances and automotive systems. *Applications of Embedded Solutions in Automation* Embedded solutions find extensive applications in the automation of diverse industries. Here are a few notable examples:

Embedded solutions have become instrumental in the realm of automation, providing powerful tools and technologies that enable seamless integration, intelligent control, and enhanced performance. These solutions combine hardware and software components to create intelligent systems capable of automating processes across various industries. In this article, we will explore the significance of embedded solutions in automation, their applications, and the benefits they bring to organizations. Embedded solutions refer to the integration of computing systems and software directly into devices, equipment, or machinery to enable automation and control. These solutions are designed to perform specific functions, offering real-time monitoring, data processing, and decision-making capabilities. Embedded systems can be found in a wide range of applications, from industrial automation and robotics to home appliances and automotive systems. *Applications of Embedded Solutions in Automation* Embedded solutions find extensive applications in the automation of diverse industries. Here are a few notable examples:

- Industrial Automation: Embedded systems power automation in manufacturing plants, controlling machinery, assembly lines, and processes. They enable precise control, monitoring of sensors and actuators, and communication with higher-level control systems, resulting in increased productivity, reduced errors, and improved operational efficiency.

- Robotics and Autonomous Systems: Embedded solutions are the backbone of robotics and autonomous systems, providing intelligence, control, and decision-making capabilities. Embedded systems enable robots to perceive their environment, navigate autonomously, and perform complex tasks with precision and efficiency. They find applications in industries such as logistics, healthcare, and agriculture.

- Smart Home Automation: Embedded solutions are at the core of smart home automation, controlling and connecting various devices and systems. They enable seamless integration of appliances, lighting, security, and HVAC systems, offering centralized control and intelligent automation to enhance comfort, energy efficiency, and security in residential settings.

- Real-time Responsiveness: Embedded systems offer real-time processing capabilities, enabling rapid data acquisition, analysis, and decision-making. This results in quicker response times, enhanced control, and improved operational efficiency.

- Improved Accuracy and Precision: Embedded solutions provide precise control over automation processes, ensuring accurate measurements, calculations, and control signals. This leads to higher product quality, reduced errors, and increased consistency.

- Flexibility and Customization: Embedded solutions can be tailored to specific requirements, allowing organizations to design systems that meet their unique needs. This flexibility enables customization, scalability, and adaptability to changing operational demands.

- Reduced Operational Costs: Embedded systems optimize resource utilization, automate repetitive tasks, and minimize errors and downtime. These factors contribute to reduced operational costs, improved productivity, and increased profitability.

- Connectivity and Integration: Embedded solutions facilitate connectivity and integration with other systems, devices, and networks. They enable seamless data exchange, communication, and collaboration, creating a unified automation ecosystem that enhances efficiency and data visibility.

Control panels are the backbone of automation systems, serving as centralized hubs for monitoring, controlling, and protecting various electrical and mechanical components. Control panel manufacturing involves the design, assembly, and testing of these panels to ensure seamless integration, reliable performance, and safety in automation processes. In this article, we will explore the significance of control panel manufacturing, the key components involved, and the benefits they bring to industrial automation. Control panel manufacturing is a critical aspect of automation, as it involves creating customized solutions that meet specific operational requirements. Control panels house essential components such as power supplies, programmable logic controllers (PLCs), human-machine interfaces (HMIs), relays, and various sensors. They provide a centralized interface for operators to monitor and control machinery, ensuring efficient and safe operation. Proper design, assembly, and testing of control panels are crucial for reliable and optimized automation systems. For More detail on Electrical Panel Manufacturing please visit our sister company page on www.voltekengineering.com *Components of Control Panel Manufacturing* Control panel manufacturing involves the integration of various components to create functional and efficient automation solutions. Here are some key components:

Control panels are the backbone of automation systems, serving as centralized hubs for monitoring, controlling, and protecting various electrical and mechanical components. Control panel manufacturing involves the design, assembly, and testing of these panels to ensure seamless integration, reliable performance, and safety in automation processes. In this article, we will explore the significance of control panel manufacturing, the key components involved, and the benefits they bring to industrial automation. Control panel manufacturing is a critical aspect of automation, as it involves creating customized solutions that meet specific operational requirements. Control panels house essential components such as power supplies, programmable logic controllers (PLCs), human-machine interfaces (HMIs), relays, and various sensors. They provide a centralized interface for operators to monitor and control machinery, ensuring efficient and safe operation. Proper design, assembly, and testing of control panels are crucial for reliable and optimized automation systems. For More detail on Electrical Panel Manufacturing please visit our sister company page on www.voltekengineering.com *Components of Control Panel Manufacturing* Control panel manufacturing involves the integration of various components to create functional and efficient automation solutions. Here are some key components:

- Enclosures: Control panels are typically housed in enclosures, which protect the internal components from environmental factors such as dust, moisture, and temperature fluctuations. Enclosures come in different sizes, materials (such as steel or aluminium), and designs to meet specific application requirements.

- Power Distribution: Control panels include power distribution components such as circuit breakers, fuses, and power supplies. These components regulate and distribute electrical power to the automation system, ensuring safe and reliable operation.

- Controllers and HMIs: Programmable logic controllers (PLCs) or other controllers are at the heart of control panels. They receive input signals from sensors, process the data, and execute control commands to operate machinery and processes. Human-machine interfaces (HMIs) provide a user-friendly interface for operators to interact with the automation system.

- Wiring and Terminal Blocks: Control panels consist of carefully routed wiring and terminal blocks to connect the various components. Proper wiring and labelling are essential for efficient troubleshooting, maintenance, and future expansions.

- Safety Devices: Control panels incorporate safety devices such as emergency stop buttons, safety relays, and interlock systems to ensure operator safety and comply with safety regulations. These devices provide a means to quickly halt operations in emergency situations.

- Low Voltage Switchgear (LV Panel )

- Power Control Centers (PCC)

- Motor Control Centers (MCC)

- HVAC control Panels

- PLC Control Panel

- Capacitor Banks

- Automatic Power Factor Correction (APFC)

- Panels Automatic Transfer Switch (ATS) Panel

- Feeder Pillars

- Main Distribution boards (MDB)

- DOL, Star-Delta & VFD Panels

- Annunciation Panel